Modern order picking, storage, and goods issue at Bünting’s 24/7 vending machine

by Katja Laska (exclusively for EuroShop.mag)

“Digitization and automation are expected to become increasingly important during the next years in efforts to promote customer value and profitable customer relationships,” says Christian Bauer, Managing Director of KHT GmbH. In this exclusive interview, he explains why that is the case, describes what it means from a logistics perspective and reveals how the technology company and its partners plan to fully embrace this trend.

©KHT GmbH

Mr. Bauer, this summer saw the introduction of the first 24/7 vending machine at Bünting in Germany. What was the key idea behind it?

This scenario is based on shifting shopping habits. Unique services, retail experiences, and services are becoming increasingly relevant to meet daily customer food needs and requirements. The idea was to team up with our partners Wanzl and Bünting and plan a pilot project in an urban environment – in a city location – and set up the first “real” 24/7 food vending machine in a retail setting.

What was KHT’s role in the implementation?

Three parties jointly supported the Bünting system with Bünting as the retail partner and pilot user, Wanzl as the market expert, and KHT as the product developer and innovative technology partner with many years of experience in automation.

Which technologies are embedded in the food vending machine?

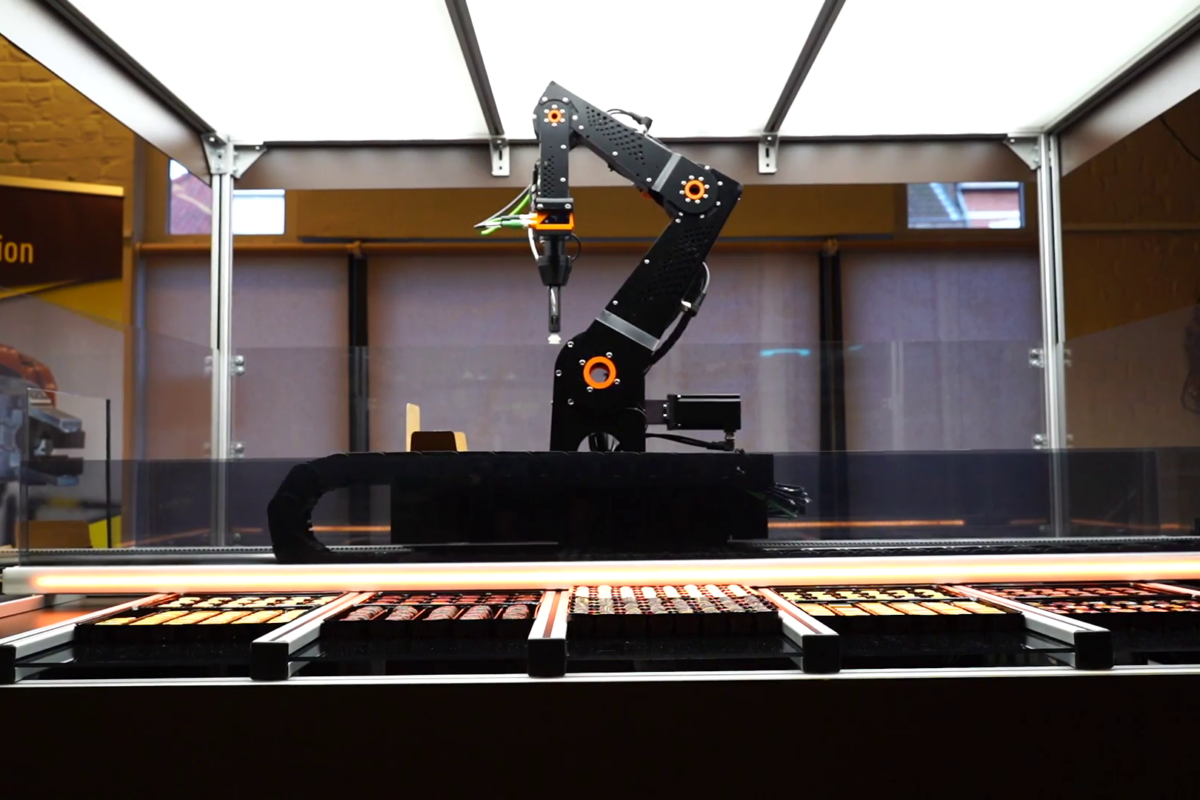

The dispensing machine is scalable in length and height. Depending on the industry sector, product, and strategic approach of category management, several thousand articles can be stockpiled in one store. The vending machine presently features a semi-automated storage process, meaning staff members place the item on a conveyor belt and the machine autonomously stores the products. An interface that is permanently connected to the customer system allows the exchange of master data and key product features. This includes information on proper cooling and age-restricted products. The items are randomly stored in the vending machine using a picking mechanism with one or two grippers. As a result, fast-moving items can be stored next to slow-moving products.

What happens when the machine is out of items?

Inventory is controlled and managed in the system via perpetual, automated inventory, monitoring and tracking of expiration dates. Inventory and movement data are passed on to the customer system to trigger inventory replenishment and to optimize the replenishment process. Our software can make this data available to the store if the solution is meant to be completely autonomous.

© Wanzl GmbH & Co.KGaA.

This obviously makes the job of employees easier. How does it affect the way customers shop?

The customer selects the desired number of products using the touchscreen and adds them to the virtual shopping cart. Products that have age restrictions, such as alcohol and tobacco require verification of age, which is done via the shopper’s ID card during payment processing. Starting in February 2021, we can make this process even easier with a specially designed mobile app. The app is another step towards the click & collect concept and drastically simplifies the process for the customer.

Online and offline: What role do warehouse automation and fulfillment technologies play today?

Automation offers solutions that meet the high and growing demands and expectations of tomorrow’s consumers. In the future, retail must focus on creating a quick, entertaining, rewarding, personalized, and secure customer experience around the clock. In the offline setting – brick-and-mortar retail- automation helps connect online and brick-and-mortar retail. It also helps save time and money in terms of staff and storage space. Space and storage density are critical aspects in showcasing customer-centric product assortments in a smaller space and creating innovative shopping experiences via digital in-store touchpoints. Even online retail giants like Amazon are moving into the brick-and-mortar market. The Knapp Group is able to provide an optimized flow of goods and information with the right technologies and create added value for our customers.

Are storage, order picking, and order fulfillment even feasible without the use of technology?

I believe only certain product groups might be able to manage without automation in the future. According to several renowned organizations, we have vaulted ten years forward in consumer and business digital adoption in a matter of three to four months. This is why automated and digitized processes are permanent and indispensable features at the point of sale. Automated systems increase the efficiency of all retail processes despite a high number of items in constantly changing product assortments

What are the vital points in your opinion?

Inventory transparency, error reduction, security and quality control in order picking are crucial aspects. The best concept offers retailers high throughput and elevated levels of accuracy and flexibility. Digital in-store systems on the retail floor make new store concepts a reality. This allows retailers to increase convenience, improve the experience for consumers and merge online and offline shopping.

Where do you see room for improvement in this industry sector?

The 2020 pandemic gave online shopping another boost as an increasing number of people buy items online. Click and collect services are a convenient option for consumers. Retail vending machines that are available 24/7/365 are a value-added benefit for shoppers and increase sales without a hefty price tag for retailers. It is important to let customers choose the level of service they prefer.

Automation and digitization change processes and support category management. Of course, both sides still have a lot to learn in this setting. And we also mustn’t forget the human factor. Changing processes put different demands on employees. That’s why education and training are critical success factors in this scenario.