Where does your T-shirt come from and where does it go?

by Julia Pott (exclusively for EuroShop.mag)

When it comes to sustainability, hardly any economic sector has been as much in the spotlight in recent years as the textile industry. From working conditions in manufacturing facilities to resource consumption, price wars and “disposable (fast) fashion” as a result of multiple fashion seasons –”sustainable economic development” is at the top of the social and political agenda.

Screenshot of the website WhereYourClohting.com

Many textile manufacturers and retailers have responded with a wide variety of approaches to production, supply chains, and business models. We took a closer look at three concepts.

Transparency starts with the first fiber – Tracking

More and more consumers choose to shop responsibly and want to know about the materials and resources their chosen products are made with and under what conditions their garments have been produced. This development prompted many companies to take a critical look at their value chain and make it more transparent.

Instead of just assuring consumers on their website that they have a sustainable supply chain, some companies are trying to facilitate traceability and allow customers to track products and processes.

Screenshot of the website WhereYourClohting.com

BRANDS Fashion is a manufacturer of sustainable workwear and uses the online tracking tool TraceMyShirt for this purpose. Based on a tracking code on the label, customers can track their products through the manufacturing process online – from cotton production to spinning, twisting, weaving, and yarn dyeing to the final production steps of cutting, printing, and finally distribution.

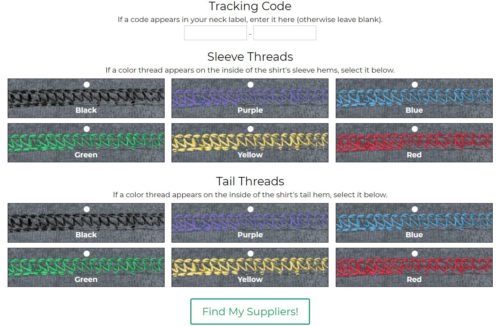

TS Designs is a textile manufacturer that takes a similar approach and is proud to produce its custom printed T-shirts entirely in the USA. The company uses contrasting stitches for its inside hems of the sleeves and tail, which allows customers to track production steps based on the thread colors and trace the production facility on the website WhereYourClothing – complete with photo, e-mail address and telephone number of the respective contact.

From old to new – Recycling and upcycling at H&M

In the 2000s, Swedish multinational clothing-retail company H&M was known and criticized for its fast-fashion, cheap, disposable clothing, which was produced under horrendous and unsustainable conditions in various Asian countries. By now, H&M – like many other companies – is committed to a more sustainable fashion culture and has made this the company’s goal and business imperative. This has prompted innovative and creative ideas, especially as it pertains to the (re)use of materials.

© Erik Lefvander/H&M

On Monday, October 12th, H&M launched a store in Stockholm that uses “Looop”, a new garment-to-garment recycling system. Old garments are placed in a machine that dissembles them and then uses the components to make yarn and produce new textiles. The idea is for customers to bring their old clothing items and watch as they are turned into something new and exciting. In a press release, Pascal Brun, Head of Sustainability at H&M, says: “We are constantly exploring new technology and innovations to help transform the fashion industry as we are working to reduce the dependency on virgin resources. Getting customers on board is key to achieve real change and we are so excited to see what Looop will inspire.”

© H&M

Upcycling is the process of transforming waste materials, useless, or unwanted products into new materials or products. This process is even more resource-efficient than the repeated use of new resources. Several examples illustrate how H&M and its affiliated brands create clothing from waste. The company’s current “bottle2fashion” initiative with Danone AQUA collects PET bottles on the islands of Indonesia and recycles them into polyester fibers. By blending them with sustainable cotton, H&M produces a kidswear collection complete with hoodies and sweatpants.

Various collections for men and women, such as the Monki brand or the new Conscious Exclusive A/W20 collection are also upcycled and crafted from waste materials. “Wear the Waste” is H&M’s collection that aims to promote a circular fashion industry versus a linear fashion economy.

Circular economy versus linear – reusing and recycling

Berlin startup circular.fashion is committed to this goal. The change agency helps interested manufacturers and retailers in fashion to create a more sustainable value chain. To this end, circular.fashion lists three key steps that have been missing so far to close the loop. Step 1: Fashion design must focus on longevity and recycling. Step 2: Products must be returned safely to the right channels when they are no longer of use. And finally Step 3: There they must be professionally sorted for complete recycling.

“Which materials are suitable for recycling? How do you design circular fashion and what are the best sorting strategies?” Answers to questions like these are found when scanning the circularity.ID tag on the garment. // © circular.fashion

The startup underwent the Fashion for Good Accelerator Programme, a platform for sustainable fashion innovation. Katrin Ley is Managing Director of Fashion for Good and considers the options provided by circular.fashion to be an important contribution to a circular fashion economy: “Innovation that helps to inform end-of-use decision making and facilitates sorting towards either re-commerce or recycling is a key enabler for circularity. By establishing a transparent flow of information between brands, consumers, sorting and recycling facilities, we take a step closer to achieving that goal.”

To get companies to embrace these processes, the Berlin-based startup offers a digital platform that helps them to make a circular product and recycle it. Circular Design Software creates unique “circularity.IDs” for garments, allowing all stakeholders – consumers, manufacturers, and recyclers – to identify the best ways to ensure circular fashion.

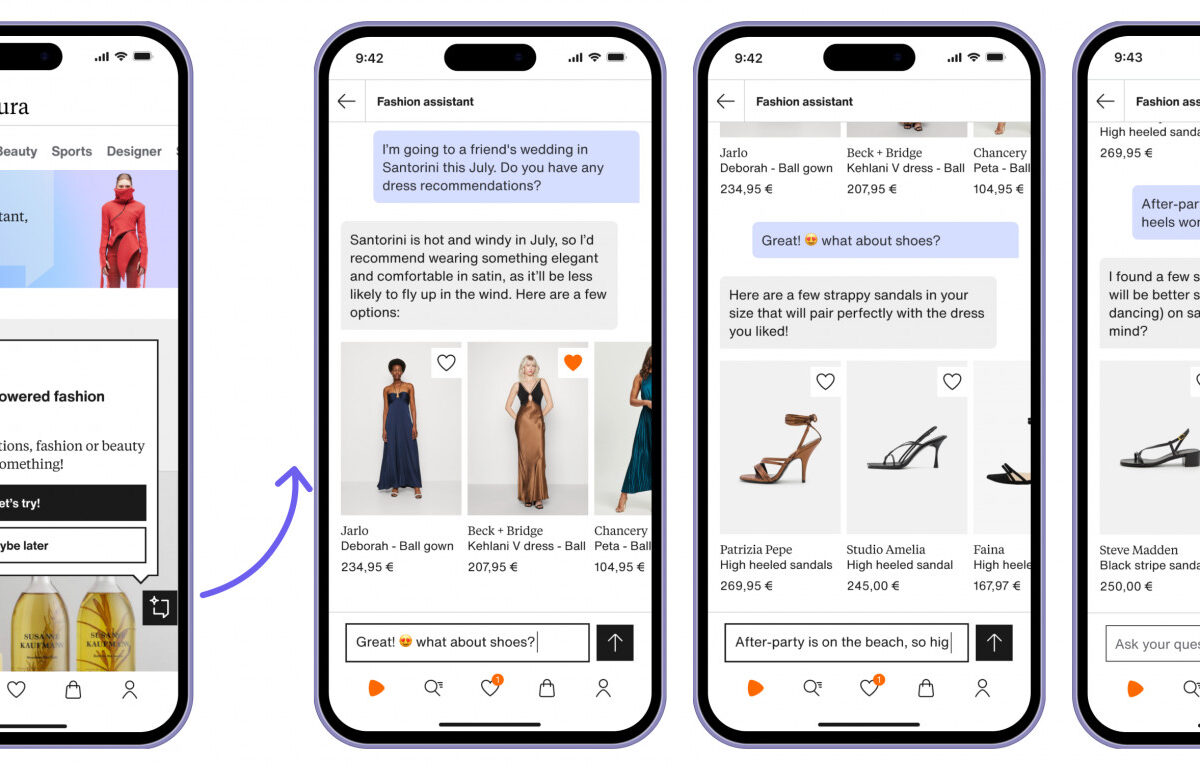

Zalando is one e-commerce company that has entered a partnership with circular.fashion and Fashion for Good. In October 2020, the online retailer announced it is testing the circularity.ID label with its private label Zign. When customers scan the codes of items in the “redeZIGN for Circularity” collection, they are taken to a product site where they can learn more about the product, the materials, care instructions, and end-of-use opportunities, such as trading their item back into Zalando’s new pre-owned category or recycling it. “We’re excited to offer our customers a collection designed with circularity principles in mind and testing an end-to-end solution that goes beyond circular design. With this pilot project, we will gather learnings on how customers value this additional level of product transparency and how it can help them extend the life of their garments”, explains Kate Heiny, Director of Sustainability at Zalando.

Sustainable economic development turns from a mere marketing ploy into a necessity. To adapt to these changes, companies must stay on the cutting edge, be willing to adopt innovation and continue to grow and evolve. The road to success is paved with innovation management that is an integral part of a company’s business model.