Belgian traditional house provides tourist attraction with low-cost automation from RBTX

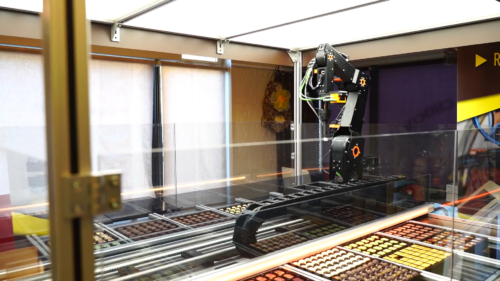

A customer enters Roose’s Chocolate World at Havenstraat 1 in Bruges. She approaches a glass box, which has the size of a small room. Inside are several displays filled with delicious chocolates in a variety of colours and shapes.

© igus GmbH

The customer puts her finger on a touchscreen terminal, puts together a collection of chocolates and places a transport box on the foot of a robot arm. One click on the enter button later, the robot starts its work. The electric assistant moves up and down the glass room, swings its arm in all directions, reaches into the displays, picks up chocolates with a suction pad, neatly places itself in the box, finally places a gold foil on the delicacies and returns to its starting position. “The customers are enthusiastic about our robot. In Bruges, Chocomatic is slowly maturing into a tourist attraction,” says Michiel Roose, son of the owners of Roose’s Chocolate World, managing director of the Belgian machine builder Roose Automation and inventor of the Chocomatic.

“For low-cost automation, almost all roads lead to RBTX”

© igus GmbH

Chocomatic is not designed to set new productivity records and replace employees. Rather, the robot primarily entertains customers. Accordingly, it was important to keep costs low without expensive licences, which many large brand suppliers work with in robotics. Roose therefore set out to find a low-cost provider. “The offer on the market is very manageable. I researched for a long time on the Internet and found out: Almost all roads currently lead to RBTX,” Roose recalls. RBTX? The abbreviation stands for a marketplace for low-cost robotics that unites manufacturers of robotic components in a modular system. The electro-mechanical basic framework is formed by robots from the Cologne-based plastics specialist igus – including jointed-arm robots, delta robots and Cartesian automats. This framework can be expanded to include individual components from other manufacturers, such as cameras, GUIs, grippers, motors, sensors and controllers. With just a few clicks, Roose put together a robotic solution from these components. “Compatibility is guaranteed because our engineers have assembled and tested all the components in various combinations,” explains Michael Hornung, product manager drylin linear and drive technology international at igus. “Users therefore enjoy investment security.”

Robot arm costs only 5,492 euros

To make Chocomatic a reality, Roose bought a robot arm called robolink from RBTX. “At 5,492 euros, the arm costs hardly more than a powerful home computer and many times less than comparable industrial robot arms, which quickly run into tens of thousands of euros,” Hornung explains. The reason for the competitive price: igus manufactures components such as the shaft gear not from metal, but from plastics – high-performance polymers optimized for maximum robustness and minimum wear. The controller for the robot costs another 1,897 euros. ” So we got a complete turnkey solution for just under 7,500 euros,” Roose is pleased to say. The operation is also cost-effective. “The tribopolymers from robolink enable dry running without lubricants,” emphasizes Hornung. “Accordingly, there are no costs for materials and maintenance.”

Visit igus GmbH at EuroShop 2023, at Hall 6 / E76, or learn more at www.igus.eu.